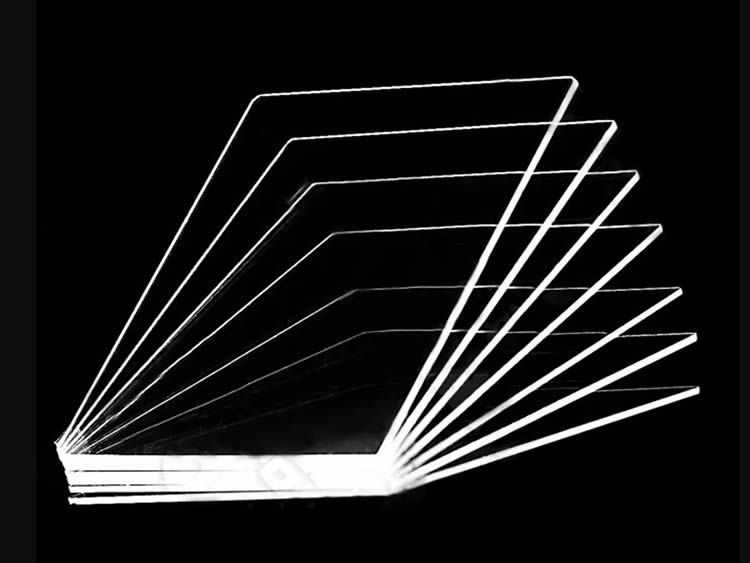

Thin Wall Rectangular Glass and Heavy Rectangular Glass

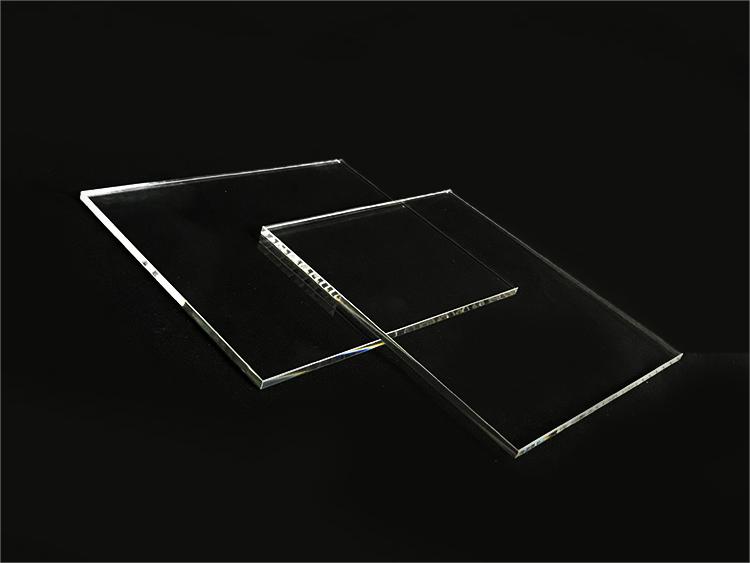

When comparing thin-walled and heavy rectangular glass, key differences include strength, durability, weight, and thermal properties. Heavy glass, being stronger and more durable, is less prone to breakage, making it suitable for high-stress applications. Conversely, the lighter and more delicate thin-walled glass is ideal for lightweight applications like picture frames and certain windows. The heavier weight of the thick glass also leads to better thermal insulation, making it apt for temperature-sensitive applications.

Thin Wall Rectangular Glass and Heavy Rectangular Glass are high-quality products made from various materials, including borosilicate glass, soda lime glass, and quartz glass. These glasses cater to a wide range of applications due to their specific material properties, catering to different temperature and stress needs.

Thin Wall Rectangular Glass

Thin /Heavy Wall Rectangular Glass

Surface Treatment

Our glass products undergo specialized surface treatments to enhance their strength and durability. For instance, our borosilicate and quartz glasses can be toughened to increase the mechanical strength of annealed glass up to five times.

Applications

The applications for these glasses are broad. For example, borosilicate glass is ideal for areas requiring high chemical resistance or higher operating temperatures, while soda lime glass is commonly used due to its affordability and strength. Quartz glass is customizable to meet the customer’s requirements.

Technical

Our borosilicate glass, per DIN 7080, withstands temperatures up to 500 degrees Celsius briefly and compressive stress up to 280 degrees Celsius, making it ideal for high-stress, high-temperature environments. Toughened borosilicate glass can tolerate temperatures up to 315 degrees Celsius, with annealed variants operating continually at 400 degrees Celsius.

Our cost-effective Soda Lime glass, conforming to DIN 8902, resists compressive stress up to 150 degrees Celsius. Toughening can increase its strength up to five times, and we can produce diameters from 3mm to 1500mm and thickness up to 25mm.

Our customizable quartz glass, made from JGS1, JGS2, or JGS3, balances affordability and resilience, potentially quintupling the strength of annealed glass.

We also offer custom thickness for non-standard aluminosilicate glass based on client requirements.

Advantages

Our thin and heavy rectangular glasses are strong, durable, and customizable. Their heat resistance and ability to handle compressive stress make them a reliable choice for various industrial applications. The use of advanced technologies like water-jet cutting machines and CNC machining centers allows us to cater to a wide range of dimensions.